ADVERTISEMENT

Preventing Spills and Breakage

Before modern plastic jugs, milk was often sold in glass bottles. While charming, glass had serious drawbacks:

- Heavy

- Fragile

- Dangerous when broken

Plastic solved many problems—but only if it could be engineered correctly.

The dent helps prevent:

- Sudden splitting when dropped

- Structural failure under weight

- Deformation during stacking

Without it, milk jugs would be far more prone to spills.

Structural Strength Without Extra Plastic

One of the most brilliant aspects of the dent is that it adds strength without adding material.

How That Works

Just like corrugated cardboard or ridges in metal beams, a change in shape:

- Increases rigidity

- Improves load distribution

- Reduces weak points

This allows manufacturers to:

- Use thinner plastic

- Lower production costs

- Reduce plastic waste

That tiny indentation helps keep millions of pounds of plastic out of landfills each year.

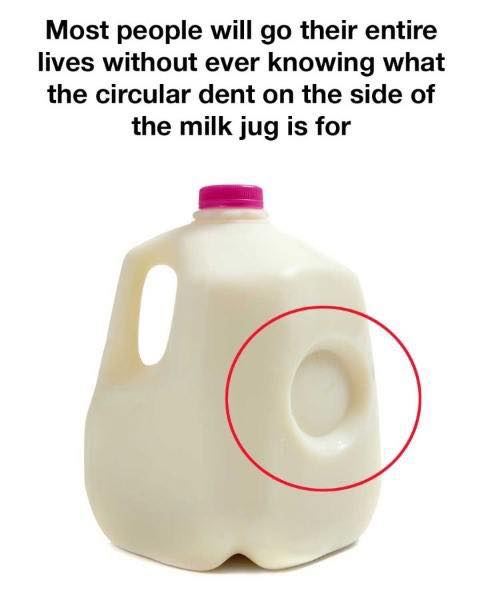

Why the Dent Is Usually Round

You might wonder why the dent is often circular or oval.

Engineers choose these shapes because:

- Curves distribute stress evenly

- Sharp angles create weak points

- Rounded dents resist cracking

It’s the same reason airplane windows are rounded rather than square.

A Safety Feature You Never Noticed

Milk jugs are stacked:

- In warehouses

- On delivery trucks

- On grocery store shelves

The dent helps the jug maintain stability under vertical pressure.

Without It:

- Jugs could collapse under weight

- Seals could break

- Milk could leak

The dent helps keep the container upright and intact until it reaches your fridge.

Temperature Changes and the Cold Chain

Milk is stored and transported through what’s called a cold chain—a controlled temperature process designed to keep dairy fresh.

During this journey, milk experiences:

- Cooling after processing

- Warming during transport

- Re-cooling in store refrigerators

Each temperature shift affects internal pressure. The dent allows the jug to adapt without failure.

ADVERTISEMENT